Inside an America's Cup team: The boat designer

We continue our "Inside an America's Cup team" series with Jason Ker, principal designer of Team Shosholoza. Ker lays out the main tasks of a boat designer in the America's Cup but also gives a more specific view on the 32nd edition of the event in Valencia.

Designing an America's Cup yacht and especially a triumphant one is one of the biggest challenges for any boat designer, even for an acclaimed one such as Ker. Nevertheless, spending 3 years working on cutting-edge technology, the design team can successfully carry out another America's Cup campaign or apply its knowhow on other major races such as the Volvo Ocean Race or the TP52 class.

Valencia Sailing: How long does it take to design an America’s Cup boat?

Jason Ker: We really started working on the original design in September 2004 and we launched the boat in June 2005, with a team of 12 people. The work of a designer often doesn’t end when construction of the boat starts, because of the extremely short timescale we were still designing when the sailors were about to go sailing for the first time. There are obviously defined dates for each piece of the boat with the deck being the first part whose design we finalized. Then, shortly after, we finalized the hull while in parallel we were working on the rig program.

In total, for Shosholoza considerable design hours were spent on the rig, as much as anything else on the yacht. The particularity of the rig system, unlike the hull and the deck, is that it has hundreds of pieces that must be designed. In addition it is related to sail design and development and it is a time consuming process. As far as sail design is concerned we have only one dedicated sail designer but he gets input from others in the design team and in particular he gets input and direction from CFD engineers regarding flying shapes to try to achieve and also in the form of numerical predictions of the performance of designed shapes. Sail design is also a good example of teamwork between the designers and sailors.

While the actual cost of designing and building an AC yacht (not including any research) could be as little as 10% of even Shosholoza’s tiny campaign budget, in reality closer to 25% is a more sensible number when proper research is included.

Valencia Sailing: RSA-83 was the first yacht to be designed from scratch under the Version 5 of the America’s Cup Rules. Did that make your task more complicated?

Jason Ker: I believe there isn’t any difference between Version 4 and Version 5 from a build point of view. We didn’t have any experience in Version 4 either but this didn’t make our job any more difficult.

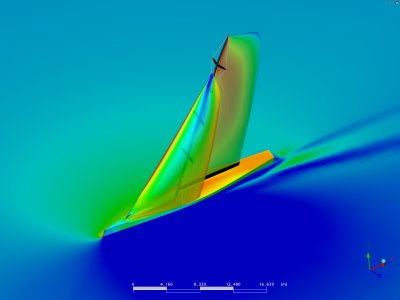

Aerodynamic computer modelling of complete upwind rig geometry of Shosholoza's RSA-83. Computation of such a model takes 3-8 hours on a cluster of 42 CPUs. Simulating the flow of air and water around the yacht is the bread and butter of an America's Cup designer.

Aerodynamic computer modelling of complete upwind rig geometry of Shosholoza's RSA-83. Computation of such a model takes 3-8 hours on a cluster of 42 CPUs. Simulating the flow of air and water around the yacht is the bread and butter of an America's Cup designer.Valencia Sailing: Are you satisfied with the boat you designed?

Jason Ker: Absolutely. We are pretty happy we what we built and we have more on the way. A new bow is being made in southern Spain with the mould being made right now. We have some other modifications for RSA-83 during the winter. We also have a new mast that is being assembled right here inside our boatshed and it just arrived two days ago from Formula Spars in the UK. In simpler words, we are “turbocharging” our racing yacht. This continuous development is an important feature of the America’s Cup. Although 18 months ago we had the newest boat in Valencia, right now it is becoming one of the oldest and we hope not to get outdated.

Valencia Sailing: How is then RSA-83 performing compared to the newer boats that were built and raced after June 2005?

Jason Ker: Now that I have observed all the new boats that were built, I would say they all have their pluses and minuses. I think the biggest differences were seen in rigs and sails. My view is that in 2006 all of the top teams had superior rigs and sails while the bottom teams had inferior ones. The differences in hulls played a much smaller role. On the contrary, I think that in 2007 differences in rigs and sails will get less pronounced as the smaller teams catch up. As a result, differences in hulls may gain importance next year.

We certainly learned some things from what the other new boats brought up and certainly from our own experiences with RSA-83. NZL-84 of Emirates Team New Zealand is an interesting boat while USA-87 of BMW Oracle is a good one as well, but it's harder to judge. Concerning Alinghi's SUI-91, I can't make a judgement since I haven't seen it racing, although I think that after building the best boats in Auckland they will probably have moved forward and built another excellent boat.

Valencia Sailing: You are one of the world's top designers of racing yachts. How much different is designing an America's Cup boat from the ones you have so far designed?

Jason Ker: Compared to other boats, the amount of time there is normally available to design an America's Cup yacht is far greater which allows us to go into minute detail. In addition, even if Shosholoza has one the smallest budgets among the teams in Valencia, you have a relatively "unlimited" budget for design in comparison to other types of design. You could say the steps in designing these boats are similar to other racing yachts but you have more time, more people involved and more resources. You do things that you normally wouldn't consider doing for a normal racing yacht. When AC designers apply themselves to other yacht design, they have effectively the same set of tools in the box but usually much less time to use them.

As a result of the design work we have done for the America's Cup, we have developed extremely good software tools and technology, what boat designers call design tools. In simple words, these tools allow you to be able to predict whether something is faster or slower, whether it will break or not. In some cases we have developed our own in-house solutions but we are also in position to know how to get the best answers from existing commercial tools. Keep in mind that it can take easily 6 months for a really good CFD (Computational Fluid Dynamics) engineer to be up and running and accurately predicting hull drag and then only if he has excellent reference data to check against.

I think I can speak for all our design team when I say that we are keen to apply our tools and knowledge not just on a future America's Cup campaign but also any of the other major racing yacht classes such as the Volvo Ocean Race or the TP52.

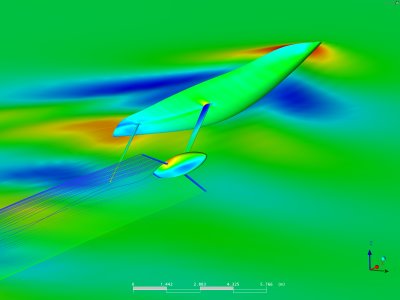

Appendage simulation for RSA-83, produced in this case by a combination of Flowlogic (the waves) and CFX. A RANS code can provide great insight into the different flow problems enabling the designer to improve performance whilst Flowlogic rapidly creates geometrically accurate waves.

Appendage simulation for RSA-83, produced in this case by a combination of Flowlogic (the waves) and CFX. A RANS code can provide great insight into the different flow problems enabling the designer to improve performance whilst Flowlogic rapidly creates geometrically accurate waves.Valencia Sailing: Have the tools you mentioned and the amazing advance in computer power made model testing obsolete?

Jason Ker: Not obsolete. We ran ten models (after we started building RSA-83) and I still think that it is the way to obtain the best results and has other advantages. The problem is that it takes a lot of time to build the model, test it and then analyze the results, however the advantage is that a test-point can be done in 20 minutes in the tank while that same point takes more like 24 hours in the computer on 20 processors for similar accuracy – a typical test in the tank might be 100 points per model and four models in a session so simple math can show that the tank is not yet obsolete...

For the new bow we are building we have entirely relied on CFD (Computational Fluid Dynamics) as again we didn’t have the time to build a model and test it in a tank and the original hull of RSA-83 was also entirely modeled through CFD but rather less advanced technology at that time. I would say that the main benefit of the tank has been the calibration of the CFD, to obtain confidence in the result the model predicts, but also it gives extra confidence before committing to build a new America's Cup hull, time permitting.

It should also be noted that for initial design computations, the team uses Flowlogic, a very advanced panel code which is capable of computing a matrix of runs overnight using just one processor. This enables the team to sift through different concepts that should be explored in more detail however a particular benefit that the team has used is that Flowlogic can be used to provide a very accurate flotation position for the Rans computations and also geometry to enable a more accurate mesh to be created.

Valencia Sailing: How important is boat design in the success of an America's Cup team?

Jason Ker: It is difficult to break it down to each individual factor. You need a good boat to win and you also need a good program and good sailors to win. It's a combination of all. You can come last with the best boat or best sailors but you can't come first unless you have almost the best of everything.

Valencia Sailing: Wind is the most important factor an America's Cup boat designer takes into consideration. What's your view on Valencia's wind patterns so far?

Jason Ker: The wind in Valencia so far has proved to be very reliable. It certainly is much more reliable than Auckland in the previous America's Cup and we haven't lost a single full day of official racing so far. On the other hand, there is less wind than promised, particularly in the early season and this is obviously taken into consideration by all designers here in Valencia. If the 32nd America's Cup were taking place in Auckland, boats would have been designed for slightly higher average wind speeds.

What is CFD?

CFD (Computational Fluid Dynamics) is one of the most important software tool for any boat designer in the America's Cup. The advances in software and hardware have made the use of such tool an integral part in the design process of all racing yachts. It basically simulates the fluid of air and water around the yacht.CFD works by dividing the region of interest, the air and water around the yacht, into a large number of cells or control volumes (the mesh or grid). In each of these cells, the partial differential equations describing the fluid flow (the Navier-Stokes equations) are rewritten as algebraic equations that relate the pressure, velocity, temperature and other variables to the values in the neighboring cells. These equations are then solved numerically yielding a complete picture of the flow down to the resolution of the grid.

Team Shosholoza’s design team use structured meshes created by ICEM but automatically linked to Geometries created by Unigraphics’ NX3 CAD software, in this way a highly refined mesh for sails, hulls or appendages can be rapidly created for new geometries.

Once the mesh is complete, the model input values are specified and the software then solves the equations of state for each cell until an acceptable convergence is achieved. This can be a time consuming process, but fast optimized codes such as CFX and Fluent can exploit parallel processing. Shosholoza's design team uses a cluster of 48 Intel Itanium CPUs located inside the team base in Valencia in addition to 64 CPUs, sometimes provided by T-Systems in Germany. The clusters in both Valencia and Stutgart are accessed across the internet by CFD engineers from South Africa and Valencia, this kind of remote computing is efficient for the very large computations required for hulls and downwind sails.

When the model has been solved, the results can be analyzed both numerically and graphically and visualized in easy-to-understand 3-D graphs...

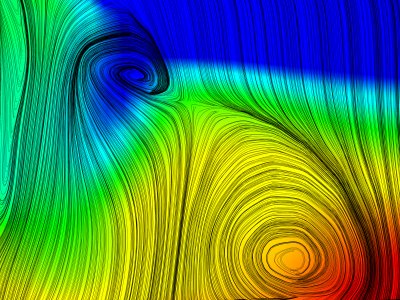

Abstract art? Could easily be. Getting good results from CFD is both an art form and a skill, especially when seeking minute differences.

Abstract art? Could easily be. Getting good results from CFD is both an art form and a skill, especially when seeking minute differences.

1 Comments:

Hello.

Just came accross your blog today.

Really enjoyed the reading you have some great material here.

I just sold my 30 catalina and i am in the process of looking for another boat. Before that i had a 25 c&c which i miss alot...

No room but did it fly...lolol

Great boat to race.

Racing the catalina was like racing a beer can...lol

I have a site that i just put up at

Nautical Gift Site no blog on it yet.

Anyways i am sure i will be talking to you again.

Again, great site.

Jamie

Post a Comment

<< Home